Farmers have a new favourite spreader!

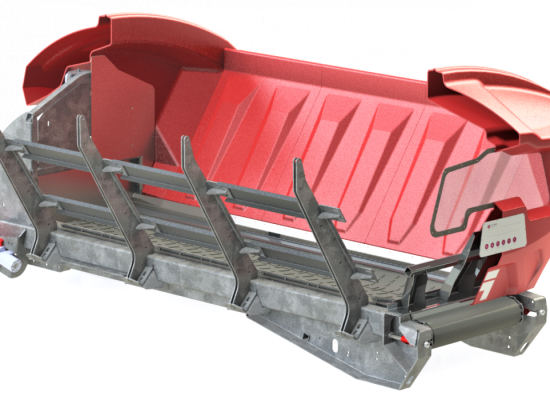

Our WideTrac Spreaders make fertiliser spreading easy, embracing intuitive 21st century technology to take care of the spreader settings at the touch of a button, a tough polyethylene plastic bin for superb corrosion resistance and outstanding styling.

We’ve thought a lot about what people really need from a fertiliser spreader.

Tough and durable to take the knocks and survive the corrosive environment of fertiliser. Easy to set up and use, and switch to different application rates quickly with no fuss. Minimal wearing parts and quick to service when you have to. A wide 780mm belt that can handle pretty much every product you’ll ever need to spread. And of course, stunning good looks!

And it's smart!

All you have to do is decide on a spreading rate, driving width and fertiliser density. Enter these 3 settings on the front control panel of the machine and then drive away. A scrolling display shows you the chosen settings and the rear spinner speed. Start and stop spreading with a remote control button from your tractor seat, and the belt speed and rear gate height will adjust automatically to suit your ground speed, and accurately deliver the rate you asked for.

These fertiliser spreaders are packed with features to make your job easier.

Watch our video where Matt chats about the key features of the Giltrap WideTrac.

Key features are also illustrated below. In addition the WideTrac has:

- The belt and spinners are driven hydraulically and the belt speed adjusts automatically as your ground speed changes. This ensures a positive and reliable drive without the hassle of v-belts or chains

- The spinner discs are hydraulically speed controlled and can spread granulated fertilisers up to 24 metres. With excellent accuracy and a wide spread means less trips around the paddock

A rigid internal steel superstructure provides strength and support for the 8mm double-skinned polyethylene bin is extremely durable and UV stabilised to withstand the elements. It is long lasting, easily maintained, resistant to corrosion, and minimises bridging

The chassis structure, drawbar and spinner assembly frame are hot dipped galvanised. The rear end of the spreader utilises stainless steel where possible, including the spinner discs and vanes. This reduces corrosion and gives extra resistance to wear and tear

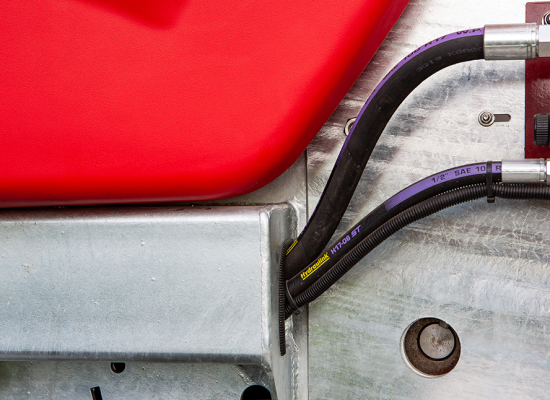

Hydraulic hoses and wiring are channeled through the chassis where possible for protection from external elements

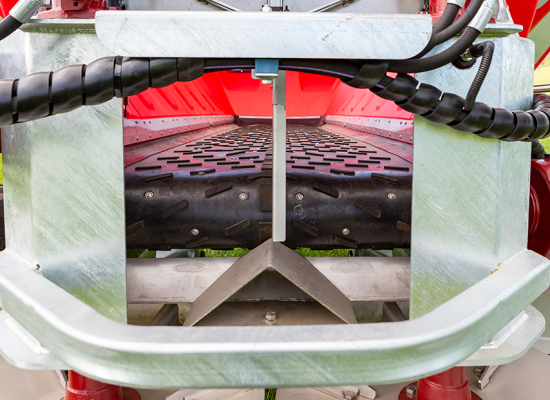

The business end of the spreader has extra corrosion and wear resistance, with stainless diverter plates and dividers to deliver an even flow of fertiliser on to stainless spinner discs, with replaceable stainless spinner flights, and stainless deflector shields.

An 8mm thick rubber belt is riveted on to steel bars which are welded to calibrated high tensile chains, and positively driven by high tensile cast sprockets. The entire chain and steel bar assembly is hot dipped galvanised after welding for corrosion resistance. Simple stainless steel tensioning adjusters keep everything running smoothly.

The 8mm spreader belt is really wide at 780mm and has a special chevron cleat pattern to grip product and transfer it to the rear spinners. This means that you can spread virtually any product which will flow. Spread chemical fertilisers such as superphosphate, urea or lime, or go the organic path with poultry manure or compost, with spreading rates between 40kg - 5000kg/hectare.

Standard features include a swivel tow eye, spinner protection bar and LED lights, ensuring your machine is visible and protected in the toughest of conditions

Technology

Perfect control

Every job is easy to set up and control with a few simple steps.

Enter the spread rate, product density and spread width, then the WideTrac automatically manages gate height and belt speed to accurately spread your valuable fertiliser.

The display is clearly visible from the tractor seat to be able to keep an eye on the spinner speed and job settings while you drive.

WideTrac Spreader Specifications

| 4T WideTrac | 6T WideTrac | 8T WideTrac | |

|---|---|---|---|

| Capacity with superphosphate (t) | 4.4 | 6.1 | 7.8 |

| Capacity with lime (t) | 5.7 | 7.9 | 10.1 |

| Capacity with urea (t) | 3.1 | 4.3 | 5.5 |

| Overall length (m) | 5.05 | 5.95 | 6.85 |

| Overall width (m) | 2.42 | 2.52 | 2.56 |

| Overall height (m) | 2.38 | 2.38 | 2.46 |

| Loading height (m) | 2.05 | 2.05 | 2.13 |

| Bin length (m) | 3.35 | 4.25 | 5.15 |

| Bin opening (m) | 1.80 | 2.70 | 3.60 |

| Tare weight (kg) | 2140 | 2360 | 2830 |

| Standard axle | Tandem | Tandem | Tandem |

| Axle size (mm) | 70 | 70 | 80 |

| Standard wheels | 11.5/80 x 15.3 | 400/60 x 15.5 | 400/55 x 22.5 |

| Recommended hydraulic flow (l/min) | 40-60 | 40 - 60 | 40-60 |