A history of innovation, born on the farm

1959

GILTRAP ENGINEERING WAS ESTABLISHED BY WILFRED GILTRAP IN OTOROHANGA.

1996

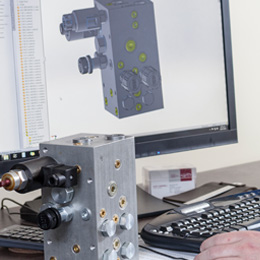

NEW ZEALAND’S FIRST SOLIDWORKS (CAD DESIGN SYSTEM) CUSTOMER. NOW REGARDED AS ONE OF THE WORLD’S LEADING ENGINEERING DESIGN SOFTWARE PACKAGES.

2001

WILFRED GILTRAP SOLD THE BUSINESS TO BELINDA AND CRAIG MULGREW.

2005

GILTRAP AG EQUIPMENT PTY LTD WAS FORMED IN AUSTRALIA TO OPERATE A LARGE WAREHOUSE IN MELBOURNE. PURCHASED DML EQUIPMENT. (FROM TAUPO ENGINEERING LTD)

2006

RELEASED NEW ZEALAND’S FIRST WIRELESS WEIGHING SYSTEM FOR FORAGE WAGONS.

2008

NEW FACTORY EXPANSION PROJECT AT OTOROHANGA AND INCREASED THE WAREHOUSE SIZE IN MELBOURNE TO MATCH THE BUSINESS GROWTH.

2009

PURCHASEDSPREADERS NZ LTD

FROM ERIC AND

MORRIS BUCKTON.

2013

PURCHASEDBUCKTON

ENGINEERING.

2014

MOVED OUR MELBOURNE BASED BUSINESS FROM A 1000 SQ.M WAREHOUSE TO A 4000 SQ.M PREMISES.

2016

ADDED ANOTHER 1500 SQ.M TO THE GILTRAP OTOROHANGA PRODUCTION FACILITY AND PURCHASED OUR FIRST LASER CUTTER.

2018

ACQUISITION OFCLOUGH AGRICULTURE,

A SEED DRILL MANUFACTURING COMPANY BASED IN TIMARU.