Built to handle all feed types, from grass, maize, whole crop cereal and silage, to long and precision cut, round or square bales, a Giltrap Forage Wagon is as versatile as it is tough.

Key Features

- Strong rugged design and construction

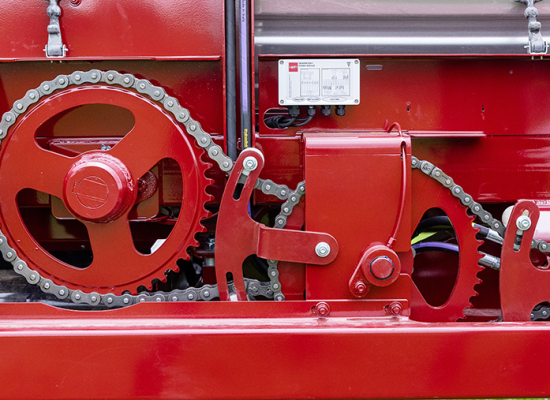

- Minimal and simplified maintenance with cast iron bushes instead of ball bearings on high load shafts, and stainless steel chain tensioners

- High-tensile 10mm calibrated link chains on the floor and elevator don’t need any maintenance and won’t seize in the acidic silage environment

- Large profile high-tensile cast chain sprockets are designed for maximum chain engagement and low wear

- Stainless steel sides provide strength with flexibility reducing corrosion and wear and tear

- Heavy-duty walking beam axles with replaceable Vesconite™ pivot bushes. Vesconite™ has built-in lubricants

- Oversized stub axles with sealed hubs

- Load sensing hydraulics ensure an even feed flow is maintained. Feed rate is adjusted manually and can be upgraded to wireless and automatic rate control linked with the optional weighing system

- All wagons are ‘scale-ready’ with a double chassis and load cell mounting points

- Mesh front screen and mesh rear back gate improves visibility and load monitoring

- Extra heavy-duty elevator bars and floor slats with secure chain attachment

- Extra-large side delivery opening, and wide belt caters for a large variety of feed products

- Internal bearings on the cross conveyor

- Centralised greasing point system for easy maintenance

- High pressure trip mechanism on the back gate

- Ladder, walkways and LED tail lights

- Swivel towing eye

Minimal and simplified maintenance with cast iron bushes instead of ball bearings on high load shafts, and stainless steel chain tensioners

High-tensile alloy forged links form part of the elevator chain assembly providing a rigid two-bolt fastening system for the elevator bars

Technology

Wireless Technology (optional)

ELECTRONIC SCALES AND RATE AUTOMATION

Our wireless scale and control technology was the first of its kind and used to relay wagon data to the monitor mounted in the tractor. Designed and manufactured by Giltrap specifically for forage wagons, and with proven in-field reliability. This system integrates scales and hydraulic feed rate control.

See Options & Accessories for further details

Giltrap RF Forage Wagon Specifications

| RF9 | RF11 | RF13 | RF16 | RF21 | RF25 | |

|---|---|---|---|---|---|---|

| Overall length (m) | 6.075 | 6.075 | 7.475 | 7.475 | 9.200 | 9.400 |

| Overall width (m) | 2.530 | 2.530 | 2.750 | 2.750 | 2.800 | 2.850 |

| Overall height (m) | 2.610 | 2.790 | 2.610 | 2.790 | 2.920 | 3.270 |

| Loading height (m) | 2.200 | 2.440 | 2.200 | 2.440 | 2.570 | 3.060 |

| Bin length (m) | 3.800 | 3.800 | 5.200 | 5.200 | 6.400 | 6.400 |

| Bin height (m) | 1.230 | 1.470 | 1.230 | 1.470 | 1.600 | 1.930 |

| Bin width (m) | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 | 2.050 |

| Tare weight (kg) | 2470 | 2620 | 3290 | 3750 | 4650 | 5680 |

| Cubic capacity (m³) | 9 | 11 | 13 | 16 | 21 | 25 |

| Conveyor belt width (mm) | 900 | 900 | 900 | 900 | 1200 | 1200 |

| No. of floor chains | 2 | 2 | 4 | 4 | 4 | 4 |

| Load cells when fitted (kg) | 4 x 5000 | 4 x 5000 | 6 x 5000 | 6 x 5000 | 6 x 5000 | 6 x 5000 |

| Jack type (mm) | 80 screw | 80 screw | 80 screw | 80 screw | 80 screw | 80 screw |

| Axle type | Tandem | Tandem | Tandem | Tandem | Tandem | Tandem |

| Axle size (mm) | 60 (6 stud) | 70 (6 stud) | 70 (6 stud) | 80 (8 stud) | 90 (8 stud) | 90 (10 stud) |

| Wheels | 11.5/80 x 15.3 | 11.5/80 x 15.3 | 400/60-15.5 | 400/55-22.5 | 500/60-22.5 | 500/60-22.5 |